Multiple layers and various techniques are involved but your end result is the boat.

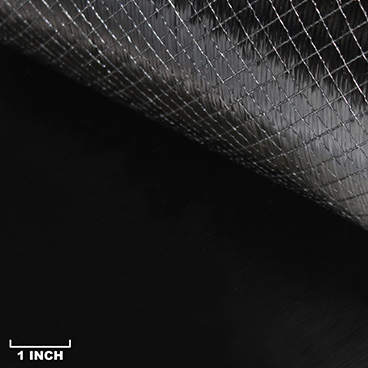

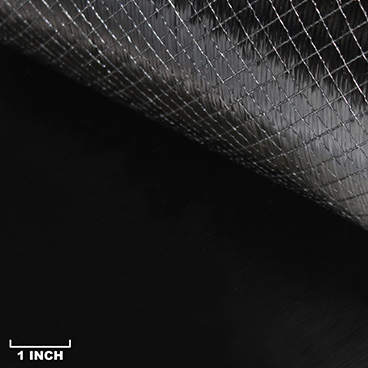

Unidirectional fiberglass laminate.

This paper investigated delamination failure in a unidirectional curved composite laminate.

The curved laminate failed unstably by delaminations developing around the curved region of the laminate at different depths through the thickness until virtually all bending stiffness was lost.

Uni weft glass is a continuous unidirectional e fiberglass laminate with 90 degree fiberglass inlay.

Acp composites fiberglass unidirectional fiber fabric is fray resistant woven with s glass and ideal for high strength lightweight precise applications.

Approximate roll length.

These fabrics are ideal as a wet lay up or resin infusion alternative to unidirectional prepreg tapes.

This combination not only gives high strength and stiffness along the longitudinal 0 axis but also provides cross strength and stiffness 90 degrees to the longitudinal axis.

X 50 e glass 0 degree unidirectional roll.

Uls bo tuff e glass is a continuous unidirectional e fiberglass laminate combined with a 50 50 woven fiberglass inlay scrim that has high strength and stiffness along the longitudinal 0 axis and provides cross strength 90 degrees to the longitudinal axis.

A unidirectional ud fabric is one in which the majority of fibres run in one direction only.

Knitted warp unidirectional 0 deg fabrics use for laminate where strength and stiffness in specific direction or plain is required.

A small amount of fibre or other material may run in other directions with the main intention being to hold the primary fibres in position although the other fibres may also offer some structural properties.

A resin in liquid form is catalyzed and applied to the fiberglass in mold.

It will cure and bond to the fiberglass chemically producing a great deal of heat called thermosetting.

It is critical that the scarf angle is set at a minimum ratio of 12 1 and that the patch thickness matches the original laminate.

Wet out quickly for excellent resin reinforcement ratio.

This diagram above illustrates how we recommend laminating a repair after the damaged fiberglass has been removed.

Delamination was assumed to initiate at the location of the highest radial stress in the curved region.