Complete dewatering was established in 1923 and began the manufacturing and development of ground water control systems to predrain and stabilize wet soils.

Vacuum well point dewatering system.

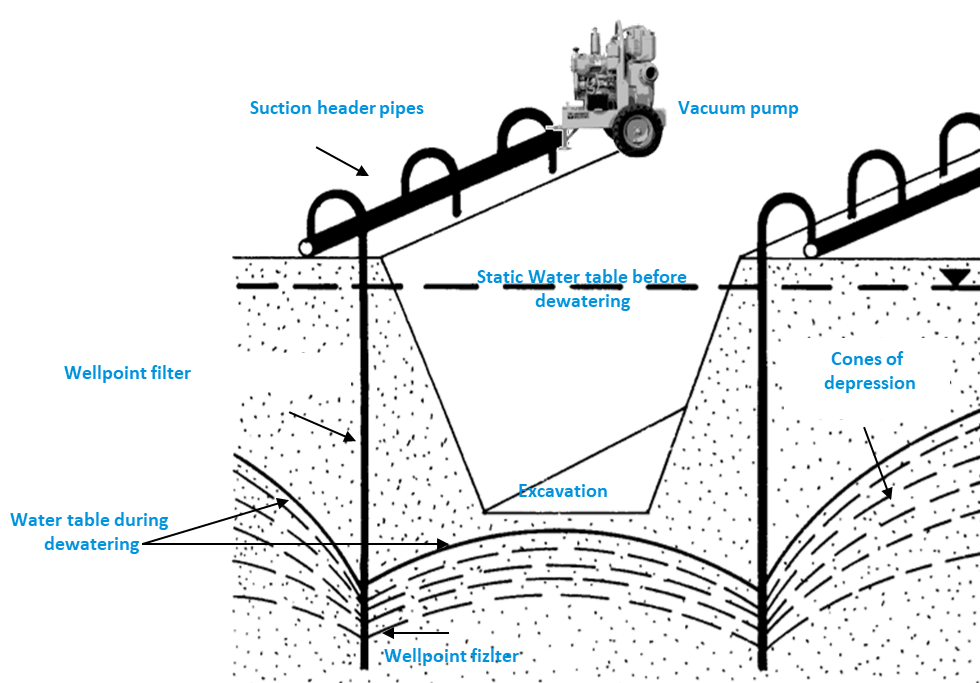

A typical wellpoint system consists of a series of small diameters wells known as wellpoints connected via a header pipe to the suction side of a suitable wellpoint pump.

Combined with griffin s line of wellpoint accessories it is easy to install and operate an efficient and complete wellpoint system.

A deep well system comprises of an array of drilled or jetted wells each fitted with an electric submersible pump.

Construction dewatering unwatering or water control are common terms used to describe.

Satyam dewatering systems is one of the leading construction dewatering companies in india.

Griffin wellpoint pumps are particularly suited for wellpoint dewatering systems in pervious soil formation.

Cdpw has been the market leader in the industry by providing innovative solutions and.

First the vacuum pressure distribution in soil is analyzed through darcy x2019 s law and.

Deep well dewatering deep well dewatering systems are used to lower groundwater levels to provide stable working conditions in excavations.

They can cope with any combination of air and water with no need for a separate priming system.

The flow of water through the nozzle generates a vacuum in the well and draws in groundwater.

Perforated wellpoints spears are placed around the construction pit and connected via dewatering hoses to hdpe header pipes.

The pump creates a vacuum in the header pipe drawing water up out of the ground.

Wellpoints cdpw specializes in the layout installation and operation of construction dewatering systems bypass pumping pump and equipment sales.

As soon as the pump is attached to a well point dewatering system you just need to start the engine and you can head off home.

The pumps are available with the wind tunnel high volume air handling system.

A wellpoint dewatering pump then creates a partial vacuum which draws the excess groundwater through the dewatering system which is then discharged via drainage pipes.

Dewatering d iː ˈ w ɔː t ər ɪ ŋ is the removal of water from solid material or soil by wet classification centrifugation filtration or similar solid liquid separation processes such as removal of residual liquid from a filter cake by a filter press as part of various industrial processes.

It is a pioneer in the arena of vaccum based well point dewatering systems sds principal business operation is well point dewatering system in the construction market which includes supply installation operation removal and abandonment of the dewatering equipment in order to make dewatering easier.

In view of this the groundwater level distribution in phreatic aquifer is analyzed.

How a well point dewatering pump works.

Ideal for shallow aquifers where the water level needs to be lowered no more than 15 or 20 feet griffin well point systems allow you to pump anything from a few gallons per minute in fine sandy silts to thousands of gallons per minute in coarse sands and gravels.

However there is little research on the groundwater level distribution under the effect of vacuum pressure which is generated by vacuum wells.