Fiber reinforced ceramic matrix composites frcmcs including c c c sic and sic sic have emerged as potential candidates for their superior physical and mechanical properties.

Ultrasonic machining ceramic matrix composites.

Introduction ceramic matrix composites cmc combine reinforcing ceramic phases with a ceramic matrix to create materials with superior properties like high temperature stability high thermal shock resistance and lightweight providing unique engineering solutions.

In contrast the effects of tool vibration on surface topography in rum of c sic composites considering fiber orientation have not been reported.

Continuous fiber reinforced sic ceramic matrix composites frcmcs sic are currently the preferred material for hot section components safety critical components and braking components in the aerospace energy transportation with high value and have triggered the demand for machining.

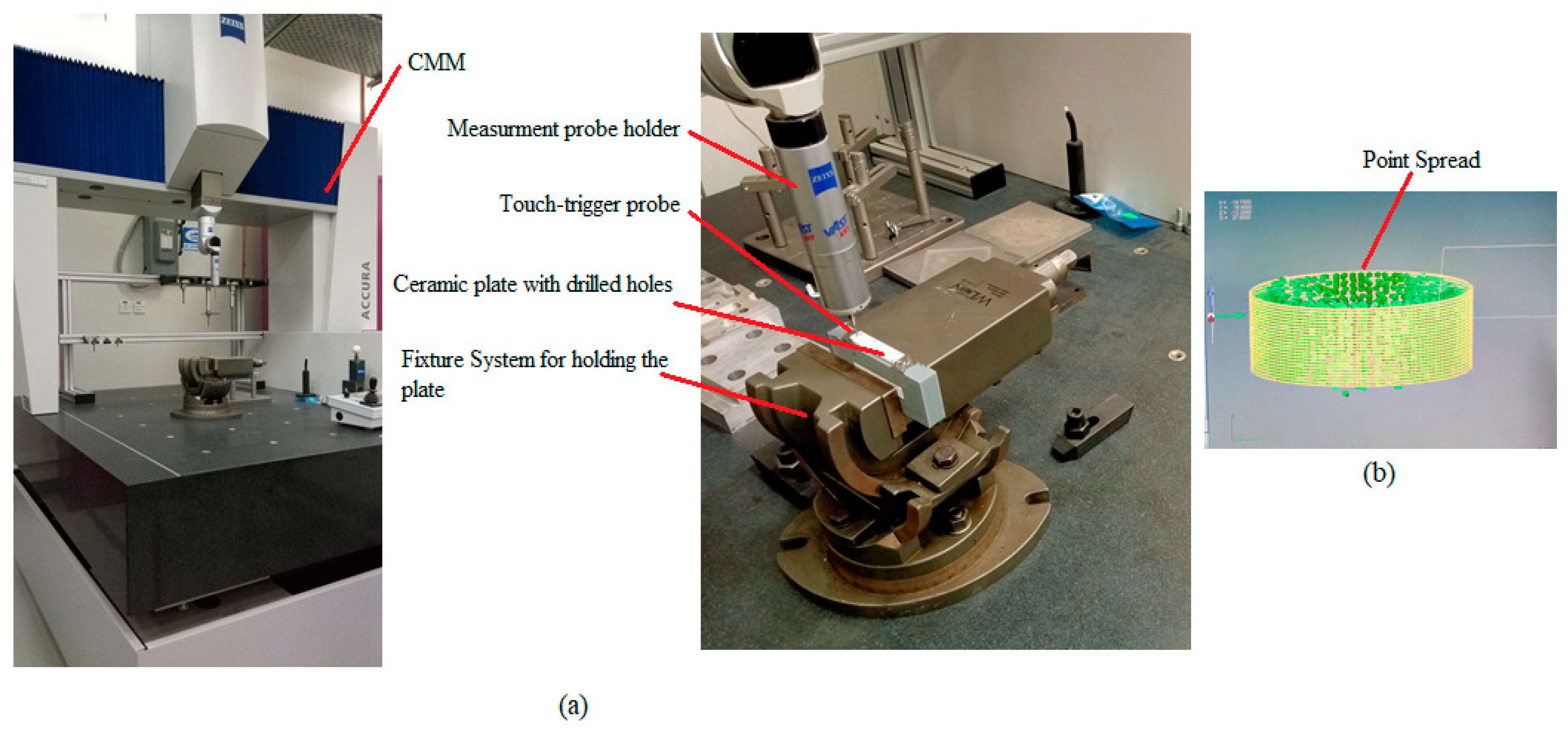

Rotary ultrasonic machining rum is a superior hole manufacturing method for ceramic matrix composites cmc with reduced cutting force and improved hole quality.

The rotary ultrasonic machining rum has been proved to be a beneficial method for c sic composites drilling with minor tearing defects at the hole exits.

For this and other critical applications customers count on bullen ultrasonics for precision machined cmcs.

Ceramic matrix composites cmc combine reinforcing ceramic phases with a ceramic matrix to create materials with superior properties like high temperature stability high thermal shock resistance and lightweight providing unique engineering solutions.

A comparison is made between rusm and conventional diamond grinding by studying the effects of material removal.

World leader in ceramic matrix composites axiom materials is the world s largest producer of oxide oxide.

Ultrasonic machining offers many advantages over conventional laser and edm machining of ceramic matrix composites.

Among various processing parameters sufficient and stable ultrasonic vibration is crucial to guaranteeing rum effectiveness in terms of cutting force reduction.

Ceramic matrix composites cmc are enabling materials for a number of high temperature and demanding applications in aerospace power generation ground transportation nuclear environmental and.

Ceramic matrix composites prepregs for parts requiring thermal performance up to 2200 f.